9 Impressive Real-world Applications of Mechanical Engineering

Mar 21, 2025 9 Min Read 22802 Views

(Last Updated)

Apart from the vehicles that you use or the equipment that you know, if I ask you what are the real-world applications of mechanical engineering, you would take too much time to answer it. That is because you are not aware of the important role that mechanical engineering plays in our lives.

Almost everything we see, use, and touch has a mechanical structure. We are so engrossed in computers and technology that we forget the study that helped to make it in the first place which is mechanical engineering. In this article, you are going to learn 9 different real-world applications of mechanical engineering that can help you understand the importance of that field.

Let’s get started.

Table of contents

- Real-world Applications of Mechanical Engineering

- Automotive Engineering

- Aerospace Engineering

- Energy Systems:

- Manufacturing Processes

- Biomechanics

- Robotics

- Material Science

- Structural Analysis and Design

- Heating, Ventilation, and Air Conditioning (HVAC) Systems

- Conclusion

- FAQ

- What skills are important for a mechanical engineer?

- What challenges do mechanical engineers face?

- What industries employ mechanical engineers?

- How does mechanical engineering contribute to sustainable practices?

- How does globalization affect mechanical engineering?

Real-world Applications of Mechanical Engineering

As the name of the section suggests, you are going to learn about some real-world applications of mechanical engineering and we curated an interesting list of 9 applications for that. Let’s go through all of them one by one.

1. Automotive Engineering

This is the widely known real-world application of mechanical engineering. This is the domain that involves the design, development, testing, and production of vehicles, including cars, trucks, motorcycles, and more.

Mechanical engineers in this field work on aspects such as engine design, chassis design, aerodynamics, safety systems, and fuel efficiency improvements. They also work on advanced technologies like electric and autonomous vehicles. This is by far one of the favorite fields of boys to work on as it involves cars and bikes.

Mechanical engineers in this field focus on creating safe, efficient, and reliable transportation solutions. Here’s a more in-depth explanation of the mechanical aspects of Automotive Engineering:

a) Engine Design and Performance:

Mechanical engineers play a critical role in designing and improving internal combustion engines. They optimize engine components such as cylinders, pistons, crankshafts, and camshafts to enhance power output, fuel efficiency, and emissions performance. This involves understanding thermodynamics, fluid dynamics, and combustion processes to create efficient and high-performing engines.

b) Chassis and Suspension Systems:

Mechanical engineers design the chassis and suspension systems that support the vehicle’s weight and provide a comfortable and stable ride. They consider factors like load distribution, impact absorption, and handling characteristics. These engineers also work on designing different types of suspensions (e.g., independent, multi-link) that balance comfort and performance.

c) Transmission and Drivetrain:

Designing transmissions and drivetrains involves optimizing gear ratios, torque transfer mechanisms, and differentials to ensure smooth acceleration and efficient power distribution to the wheels. Mechanical engineers focus on minimizing power losses and improving gear-shifting mechanisms for both manual and automatic transmissions.

d) Aerodynamics and Body Design:

Automotive engineers consider aerodynamics to reduce drag and improve fuel efficiency. Mechanical engineers analyze airflows around the vehicle and design the body shape to minimize resistance. They also collaborate with aerodynamicists to integrate components like spoilers, diffusers, and underbody panels for enhanced stability and reduced air resistance.

e) Safety Systems and Crashworthiness:

Mechanical engineers are responsible for designing safety systems that protect occupants during collisions. They develop crumple zones, impact-absorbing materials, and restraint systems (e.g., airbags, seat belts) to manage and minimize the forces experienced in a crash. These engineers also conduct simulations and tests to ensure the vehicle’s crashworthiness.

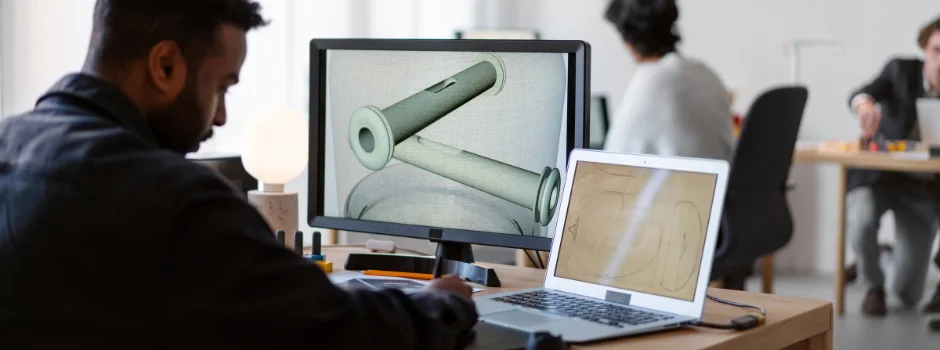

Before we move on to the next part, you should have a deeper knowledge of key mechanical engineering concepts. You can consider enrolling yourself in GUVI’s CAD Program for Mechanical Engineers, which lets you gain practical experience by developing real-world projects and covers technologies including AutoCAD, Solidworks, CATIA, Ansys, GD & T, etc.

Additionally, if you would like to explore AutoCAD for Mechanical Engineering through a self-paced course, you can take GUVI’s AutoCAD Mechanical Certification Course.

2. Aerospace Engineering

Though there is a field that is specified for aerospace, mechanical engineering plays a huge role in it. Since the field of aerospace involves complex systems like structural design, materials selection, and so on, it comes down to mechanical engineers who play a crucial role in analyzing these systems.

Aerospace engineering is a specialized field within mechanical engineering that focuses on the design, development, testing, and production of aircraft, spacecraft, satellites, and related systems. Here’s an explanation of the application of aerospace engineering from a mechanical point of view:

a) Aerodynamics and Fluid Mechanics:

A major aspect of aerospace engineering involves understanding and manipulating the behavior of fluids (air and gases) around vehicles in flight. Mechanical engineers in aerospace design airfoil shapes, wings, and other aerodynamic surfaces to optimize lift, drag, and stability. They use principles of fluid dynamics to predict how airflows over different surfaces, which is crucial for achieving efficient flight and safe operation of aircraft and spacecraft.

b) Structural Design and Materials Selection:

Mechanical engineers in aerospace are responsible for designing the structural components of vehicles that can withstand the forces experienced during flight. They select appropriate materials, such as lightweight composites and metals with high strength-to-weight ratios, to ensure the vehicle’s structural integrity. These materials must withstand extreme temperature variations, vibrations, and stress loads encountered during launch, flight, and re-entry.

c) Propulsion Systems:

Aerospace engineers work on propulsion systems, including jet engines, rocket engines, and other forms of propulsion used in space travel. Mechanical engineers within this domain design and analyze the components of these systems, such as turbines, combustion chambers, nozzles, and fuel systems. They optimize these systems for efficiency, thrust, and safety, considering factors like combustion dynamics and thermal management.

d) Thermal Management:

Aircraft and spacecraft operate in environments with significant temperature variations. Mechanical engineers ensure that the vehicle’s components are designed to handle these extreme temperatures. They develop heat shields, thermal insulation, and cooling systems to protect sensitive equipment and maintain operational efficiency.

3. Energy Systems:

The era of sustainability and reduction in emission of greenhouse gases has started and it is the role of a mechanical engineer to contribute in a much greater aspect by designing and optimizing various energy systems, including power plants, renewable energy systems (such as wind and solar), and energy-efficient HVAC (Heating, Ventilation, and Air Conditioning) systems for buildings.

They also work on improving energy conversion efficiency, reducing emissions, and developing sustainable energy solutions. Here’s how mechanical engineering plays a role in energy system management:

a) Power Generation Systems:

Mechanical engineers play a vital role in designing and improving power generation systems, such as steam turbines, gas turbines, and internal combustion engines. They focus on maximizing the efficiency of energy conversion processes by optimizing combustion, heat transfer, and fluid dynamics within these systems. Mechanical engineers also work on innovations in renewable energy sources, such as wind turbines and solar panels, to harness clean and sustainable power.

b) Renewable Energy Systems:

Mechanical engineers work on designing and implementing renewable energy technologies such as solar photovoltaic (PV) systems and wind turbines. They optimize the design of solar panels to capture sunlight efficiently and develop wind turbine designs that maximize energy extraction from wind flows.

c) Energy Storage Systems:

Energy storage is a critical component of modern energy systems. Mechanical engineers contribute to the design and development of energy storage technologies like batteries, flywheels, and pumped hydro storage. They focus on improving energy density, charging and discharging efficiency, and the overall lifespan of energy storage systems.

d) Distributed Energy Systems:

Mechanical engineers also contribute to the development of distributed energy systems, where power generation and consumption are localized. This includes microgrids, where local energy sources and storage are integrated to provide power resilience and reduce dependency on centralized grids.

e) Environmental Impact Mitigation:

Mechanical engineers play a role in minimizing the environmental impact of energy systems by designing cleaner and more efficient technologies. This can include emission control systems for fossil fuel-based power plants or implementing carbon capture and storage (CCS) technologies.

4. Manufacturing Processes

Mechanical engineers contribute to the development and optimization of manufacturing processes, from traditional techniques like machining and casting to modern technologies such as additive manufacturing (3D printing). They focus on improving product quality, production efficiency, and cost-effectiveness.

Manufacturing processes are a core aspect of mechanical engineering that involves the conversion of raw materials into finished products through various methods and techniques. Here’s an explanation of the process of it:

a) Machining:

Machining processes involve the removal of material from a workpiece to create the desired shape and dimensions. Mechanical engineers are responsible for selecting the appropriate machining techniques, such as turning, milling, drilling, and grinding, based on the material properties and the required precision. They design machine tools, cutting tools, and fixtures to ensure accurate and efficient material removal.

b) Casting:

Casting is a process where molten material is poured into a mold to create complex shapes. Mechanical engineers design molds, optimize the casting process parameters, and select suitable casting materials. They ensure proper cooling and solidification to minimize defects and achieve the desired product properties.

c) Forming and Forging:

Forming processes involve shaping materials through the application of force. Mechanical engineers design tools and dies for processes like stamping, bending, and extrusion. Forging involves shaping metal through localized compression, and mechanical engineers optimize the forging process to enhance material properties and structural integrity.

d) Additive Manufacturing (3D Printing):

Additive manufacturing is a modern technique where materials are added layer by layer to create complex parts. Mechanical engineers work on selecting appropriate printing materials, optimizing printing parameters, and designing components for additive manufacturing. For this, they use CAD (Computer-aided Design) software to make sure the design is proper and can have the look of a prototype before printing it out.

e) Surface Treatment and Finishing:

Surface treatments like plating, coating, and heat treatment are crucial to enhance the properties and durability of parts. Mechanical engineers select appropriate surface treatments, ensuring the right coating thickness, adhesion, and corrosion resistance.

f) Quality Control and Inspection:

Mechanical engineers develop quality control methods to ensure that manufactured parts meet specifications. They design inspection processes using techniques such as coordinate measuring machines (CMMs), non-destructive testing (NDT), and visual inspections.

5. Biomechanics

Biomechanics is the field that applies principles of mechanics to understand the mechanics of biological systems, including the human body.

Mechanical engineers play a significant role in the application of biomechanics, focusing on the analysis, design, and improvement of mechanical systems within the context of biological organisms. This can include designing medical devices such as prosthetics, orthotics, and implants and understanding how forces and stresses affect the human body in activities like walking, running, and sports.

Here’s an explanation of the real-world application of mechanical engineering on biomechanics:

a) Prosthetics and Orthotics:

Mechanical engineers design prosthetic limbs and orthotic devices to assist individuals with limb loss or mobility impairments. They focus on creating lightweight and comfortable devices that mimic natural human movements, ensuring proper fit, alignment, and biomechanical functionality.

b) Implantable Medical Devices:

Biomechanical engineers work on the design and development of implantable medical devices, such as joint replacements, pacemakers, and artificial heart valves. They consider factors like material selection, compatibility with body tissues, and biomechanical interactions to ensure the safety and effectiveness of these devices.

c) Sports Equipment and Apparel:

Mechanical engineers in biomechanics design sports equipment and apparel to enhance athletic performance and prevent injuries. They optimize the design of footwear, helmets, protective gear, and other equipment to provide proper support, shock absorption, and biomechanical advantages.

d) Biomechanics of Injury Prevention:

Biomechanical engineers study the mechanics of injury mechanisms, such as impact forces during accidents. They design safety equipment, like helmets and seat belts, to mitigate the effects of impact and reduce the risk of severe injuries.

e) Human-Machine Interaction:

Mechanical engineers in biomechanics design interfaces between humans and machines, considering factors like comfort, ease of use, and biomechanical compatibility. This includes designing controls for vehicles, machines, and medical devices.

f) Muscle Mechanics and Rehabilitation Robotics:

Biomechanical engineers study muscle mechanics to develop rehabilitation robots and exoskeletons that assist individuals with limited mobility. These devices use mechanical principles to provide controlled movements and aid in muscle retraining.

6. Robotics

Robotics is a field of engineering that involves the design, construction, operation, and use of robots. Mechanical engineers play a crucial role in the application of robotics, as they focus on the mechanical aspects of designing and building robotic systems.

They also work on mechanisms, sensors, actuators, and control systems to create robots capable of performing tasks with precision and efficiency.

Let’s understand more about the real-world application of mechanical engineering in the field of robotics:

a) Mechanical Design of Robots:

Mechanical engineers design the physical structure and components of robots. This includes creating the robot’s body, joints, arms, grippers, and other mechanical parts. They ensure that the design is robust, lightweight, and capable of performing the required tasks with precision.

b) Kinematics and Dynamics:

Mechanical engineers work on the kinematics (movement) and dynamics (forces and torques) of robotic systems. They design the robot’s joints and linkages to achieve the desired range of motion and accuracy. They also analyze the forces and torques at various joints to ensure stability and safety during operation.

c) Actuators and Sensors:

Actuators are devices that enable robots to move their limbs and perform actions. Mechanical engineers choose and design actuators such as motors, servos, and pneumatics to create the desired motions. They also integrate sensors (like cameras, tactile sensors, and distance sensors) that provide feedback to the robot about its environment and interactions.

d) Robotics Automation and Manufacturing:

In industrial settings, mechanical engineers use robotics to automate manufacturing processes. They design robotic systems that can perform tasks like assembly, welding, painting, and quality inspection. This increases efficiency, reduces human labor, and enhances product consistency.

e) Medical Robotics:

Mechanical engineers contribute to the design of medical robots used in surgeries, diagnostics, and patient care. These robots require high precision and reliability, and mechanical engineers ensure that they meet stringent safety and hygiene standards.

7. Material Science

Material science is a field that explores the properties, behavior, and applications of various materials. In the context of mechanical engineering, material science plays a critical role in selecting, designing, and optimizing materials for use in mechanical systems.

They design materials with specific properties to suit different environments and applications, from lightweight and strong materials for aerospace to durable and heat-resistant materials for industrial processes.

Here’s a detailed understanding of material science as one of the real-world applications of mechanical engineering:

a) Material Selection:

Mechanical engineers choose materials based on their mechanical properties, such as strength, stiffness, toughness, and fatigue resistance. Material scientists help identify materials that can withstand the specific mechanical loads and conditions a component will experience.

b) Structural Integrity:

Material scientists analyze how materials respond to different stress and strain conditions. They ensure that materials used in mechanical systems maintain their structural integrity, resisting deformation and failure over time.

c) Materials for Extreme Environments:

Mechanical engineers often deal with extreme conditions, such as high temperatures, corrosive environments, and radiation. Material scientists develop materials with properties that can withstand these conditions, ensuring the longevity and reliability of mechanical systems.

d) Heat Treatment and Surface Engineering:

Material science helps mechanical engineers improve material properties through techniques like heat treatment and surface engineering. Heat treatment can enhance the strength or hardness of materials, while surface engineering techniques like coating and nitriding improve wear resistance and corrosion protection.

e) Fatigue and Fracture Analysis:

Material scientists study the behavior of materials under cyclic loading and investigate factors that lead to fatigue and fracture. This knowledge helps mechanical engineers design components that can withstand repetitive loads without failing.

f) Materials Testing and Characterization:

Materials scientists develop and perform tests to characterize mechanical properties, such as tensile strength, hardness, and impact resistance. This data is crucial for mechanical engineers to make informed decisions about material selection and performance.

8. Structural Analysis and Design

Structural analysis and design is a fundamental aspect of mechanical engineering that involves the study of how materials and components respond to various loads, forces, and environmental conditions.

It focuses on ensuring the structural integrity, safety, and functionality of mechanical systems. They also analyze stresses, strains, and vibrations to ensure the structural integrity and safety of these systems.

a) Load Analysis:

Mechanical engineers analyze the loads that a structure or component will experience during its operational life. These loads can include forces, moments, vibrations, thermal effects, and more. Understanding these loads is essential for designing components that can withstand them without failure.

b) Stress and Strain Analysis:

Structural analysis involves calculating the stresses and strains within a component or structure under different loads. Mechanical engineers ensure that the stresses and strains remain within safe limits to prevent permanent deformation or failure.

c) Material Selection:

Mechanical engineers choose materials based on their mechanical properties, such as strength, stiffness, and ductility. They consider the compatibility of materials with the anticipated loads and conditions to ensure that components can perform their intended functions without compromising safety.

d) Design Optimization:

Structural design aims to optimize the geometry and configuration of components to achieve the desired performance while minimizing weight, cost, and material usage. Mechanical engineers balance factors like load-bearing capacity, stability, and efficiency in their designs.

e) Safety Factor and Reliability Analysis:

Mechanical engineers apply safety factors to design against unexpected variations in loads, material properties, and manufacturing processes. Reliability analysis assesses the probability of failure and helps engineers make informed decisions about design modifications and materials.

9. Heating, Ventilation, and Air Conditioning (HVAC) Systems

Heating, Ventilation, and Air Conditioning (HVAC) systems are essential for creating comfortable and controlled indoor environments in buildings. Mechanical engineers play a pivotal role in the design, installation, and maintenance of HVAC systems.

HVAC systems are essential for maintaining a conducive environment in residential, commercial, and industrial spaces. Let us understand about it in detail:

a) Heating Systems:

Mechanical engineers design heating systems that provide warmth to indoor spaces. This involves selecting heating sources such as furnaces, boilers, heat pumps, or electric heaters. Engineers analyze factors like heating load calculations, energy efficiency, and distribution methods to ensure even and effective heating throughout the building.

b) Cooling Systems:

Mechanical engineers design cooling systems to manage indoor temperatures during hot weather. This includes selecting cooling equipment such as air conditioners, chillers, and evaporative coolers. Engineers calculate cooling loads, design ductwork and air distribution systems, and optimize cooling efficiency.

c) Air Distribution and Ductwork:

Mechanical engineers design the layout of ductwork, diffusers, and vents to ensure efficient air distribution throughout the building. They consider factors such as air velocity, pressure drops, and noise levels to achieve proper airflow and thermal comfort in each room.

d) Air Quality and Filtration:

HVAC systems play a crucial role in maintaining indoor air quality. Mechanical engineers incorporate air filtration systems that remove contaminants, pollutants, and allergens from the air, ensuring a healthier and more comfortable environment for occupants.

e) Humidity Control:

HVAC systems manage indoor humidity levels, which impact comfort and health. Mechanical engineers design systems that regulate humidity through dehumidification and humidification processes, preventing issues like mold growth and discomfort.

f) Noise and Vibration Control:

HVAC systems can produce noise and vibrations that impact indoor comfort. Mechanical engineers design systems with noise insulation, vibration dampening, and proper equipment placement to minimize unwanted sounds and vibrations.

Kickstart your career by enrolling in GUVI’s CAD Career Program for Mechanical Engineers where you will master technologies including AutoCAD, Solidworks, CATIA, Ansys, GD & T, etc, and build interesting real-life mechanical projects.

Alternatively, if you would like to explore AutoCAD for Mechanical Engineering through a self-paced course, you can take GUVI’s AutoCAD Mechanical Certification Course.

Conclusion

In conclusion, the world of mechanical engineering is full of innovation and transformation that has a crucial role in every part of our lives.

Its applications span across industries, from aerospace and automotive to healthcare and energy proving that mechanical engineering is not dead but still very much alive.

As we set our feet towards the future and embrace the modern age, it’s important to recognize the impressive work of mechanical engineers who continuously push their boundaries, refine designs, and strive for excellence.

FAQ

Key skills for a mechanical engineer include proficiency in mathematics, problem-solving, technical drawing, CAD software, knowledge of materials, analytical thinking, communication, and a strong grasp of physics and mechanics.

Mechanical engineers often tackle challenges like designing energy-efficient systems, ensuring product reliability, adapting to rapidly evolving technology, meeting safety and regulatory standards, and balancing cost-effectiveness with performance.

Mechanical engineers find employment in industries such as aerospace, automotive, manufacturing, energy, robotics, healthcare, consumer electronics, and more.

Mechanical engineers work on designing energy-efficient systems, renewable energy technologies, efficient transportation systems, and environmentally friendly manufacturing processes to promote sustainability.

Globalization presents opportunities and challenges for mechanical engineers, as they work across international boundaries, collaborate with diverse teams, and adapt designs to meet different market needs and regulations.

![A Complete Look on Mechanical Engineer's Salary in India [2025] 14 Feature image - A Complete Look on Mechanical Engineer’s Salary in India](https://www.guvi.in/blog/wp-content/uploads/2023/09/Feature-image-A-Complete-Look-on-Mechanical-Engineers-Salary-in-India.webp)

Fascinating read! It's incredible to see the diverse real-world applications of mechanical engineering, from robotics and automotive innovations to renewable energy solutions. These examples highlight the impact of engineering on everyday life and the future of technology. It's inspiring for anyone in the field or considering it as a career path.