7 Important Roles and Responsibilities of a Mechanical Engineer

Jun 10, 2025 7 Min Read 23389 Views

(Last Updated)

Technological development is skyrocketing over the years, and because of this, we forget the basic foundation that has been laid to make this progress, which is mechanical engineering. Everything around us, from mobiles to kitchen appliances to vehicles to industry-grade equipment, is mechanical engineering behind everything. But, do you know the roles and responsibilities of a mechanical engineer?

That is what we are going to see in this article. It is important to understand the roles and responsibilities of a mechanical engineer because there is more to it and not only just manufacturing and production. So, let’s get started with our journey in exploring the roles and responsibilities of mechanical engineers.

Table of contents

- What is Mechanical Engineering?

- Skills Required for Mechanical Engineering

- Technical Proficiency

- Mathematics and Physics

- Problem-Solving Abilities

- Mechanical Systems and Materials Knowledge

- Roles and Responsibilities of a Mechanical Engineer

- Design and Development

- Analysis and Testing

- Project Management

- Manufacturing and Production

- Quality Assurance and Control

- Maintenance and Repair

- Research and Innovation

- Conclusion

- FAQ

- What are some common applications of mechanical engineering?

- Is programming knowledge important for mechanical engineers?

- What challenges do mechanical engineers face in today's world?

- How do mechanical engineers contribute to innovation?

- What does the future hold for mechanical engineers?

What is Mechanical Engineering?

Once upon a time, the department that was famous among most Indians, especially boys was mechanical engineering. It had so much craze that in every other college-based movie, the protagonist would always seem to be pursuing mechanical engineering. Before we go with the skills required for mechanical engineering, let us understand what mechanical engineering is all about.

Mechanical engineering is a branch of engineering that focuses on the design, analysis, development, and maintenance of mechanical systems and devices. It encompasses a wide range of activities related to the creation of physical objects and systems that involve moving parts, energy transfer, and the application of mechanical principles.

Mechanical engineers use their knowledge of physics, mathematics, materials science, and other engineering disciplines to design and create various mechanical systems and devices. These can include everything from simple components to complex machines.

Now you know why I said that mechanical engineering is not an easy subject. It involves every subject and requires intricate knowledge of it.

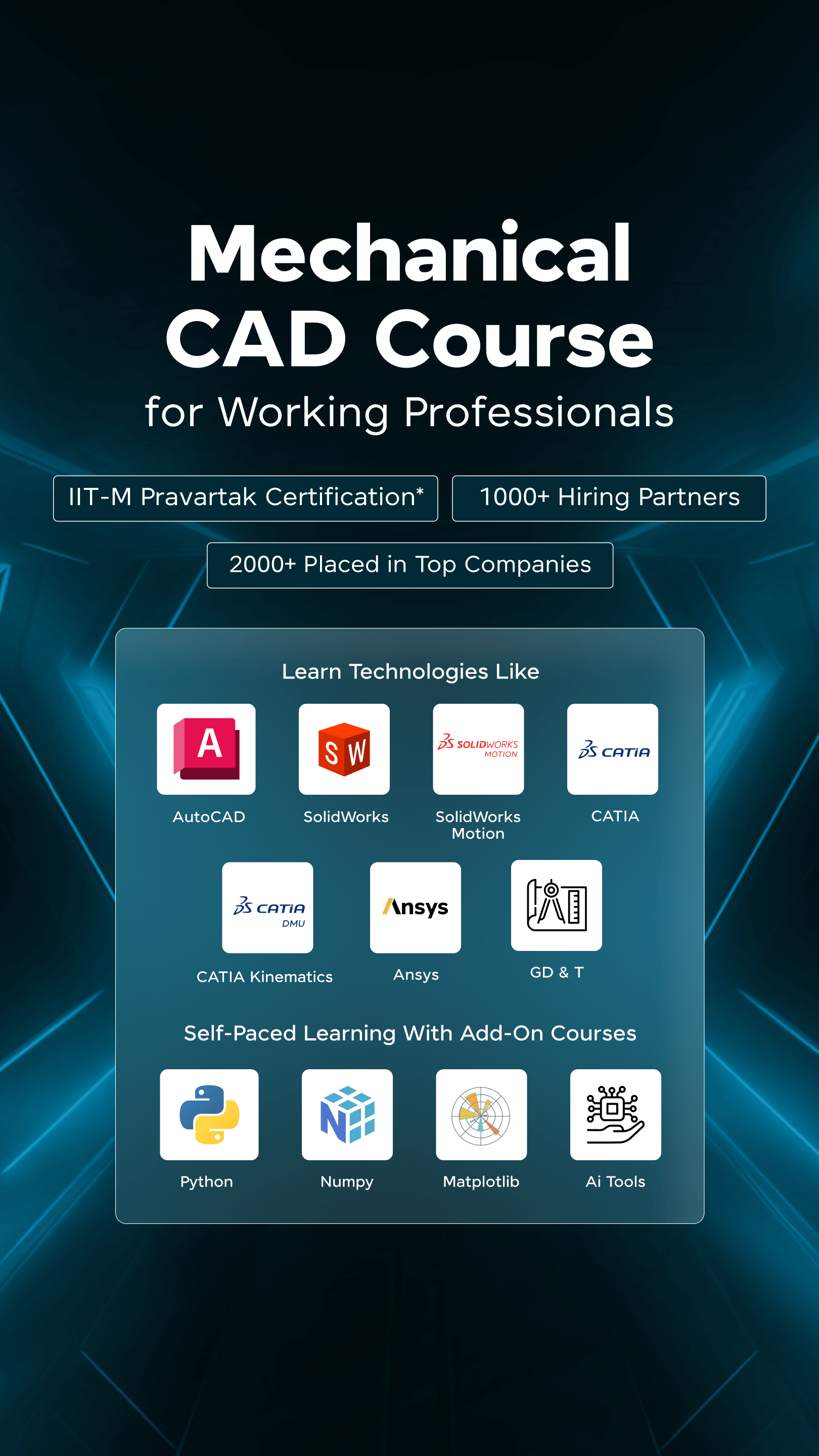

Kickstart your career by enrolling in GUVI’s CAD Course for Mechanical Engineers, where you will master technologies including AutoCAD, Solidworks, CATIA, Ansys, GD&T, etc, and build interesting real-life mechanical projects.

Skills Required for Mechanical Engineering

Before we understand the roles and responsibilities of a mechanical engineer, let us first see the skills that are required for mechanical engineering. We already have a blog dedicated solely to this, so I’ll be covering only the major points here. These are the basic skills that are required for a mechanical engineer:

1. Technical Proficiency

Technical proficiency is essential in mechanical engineering because it’s like the toolbox that helps engineers understand and solve problems related to machines and structures.

Imagine building a puzzle; you need to know how the pieces fit together, or you’ll end up with a mess. In the same way, mechanical engineers use their technical skills to design, analyze, and fix mechanical stuff like engines, robots, or buildings.

Things that you need to know about this skill are:

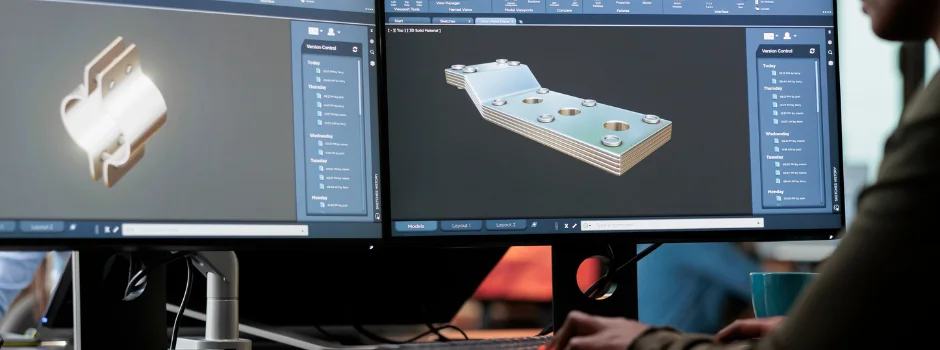

- CAD Software: Proficiency in CAD (Computer-Aided Design) software is essential. These tools allow engineers to create detailed 2D and 3D models of mechanical components and systems. It involves creating accurate representations of designs and considering dimensions, tolerances, and assembly processes.

- Simulation and Analysis: Mechanical engineers use software tools like ANSYS, COMSOL, and MATLAB for simulation and analysis. They simulate how mechanical systems will behave under various conditions, such as stress, temperature, and fluid flow. This helps in predicting potential issues and optimizing designs before physical prototypes are created.

- Technical Drawing: Understanding technical drawings, which include orthographic projections, sections, and isometric views, is vital. Engineers need to read and create these drawings to communicate design specifications to manufacturers and other team members accurately.

Alternatively, if you would like to explore AutoCAD for Mechanical Engineering through a self-paced course, you can take GUVI’s AutoCAD Mechanical Certification Course.

2. Mathematics and Physics

Mathematics and physics are like the foundation of a strong building in mechanical engineering. Think of math as the language we use to describe how things move, change, and interact in the world of machines and structures.

Physics helps us understand why things behave the way they do. When you design a car engine or a bridge, you need math to calculate forces, stresses, and how materials will hold up. Physics helps you figure out how heat, gravity, and all the forces in play will affect your design.

Without these two, it’s like trying to build something without knowing the rules of the game.

- Mathematics: A strong foundation in mathematics is crucial. Calculus helps in understanding rates of change and optimization, while linear algebra is essential for dealing with systems of equations. Differential equations are used to model dynamic systems.

- Physics: Mechanical engineering heavily relies on physics principles. Mechanics covers how objects move and interact under forces, while thermodynamics deals with heat and energy transfer. Fluid dynamics is important for understanding the behavior of fluids in various systems.

3. Problem-Solving Abilities

Problem-solving abilities are super important in mechanical engineering because they’re like the superhero skills that help engineers tackle tricky challenges.

Imagine you’re building a robot, and it suddenly stops working. You need to figure out what went wrong and how to fix it. That’s where problem-solving comes in.

Mechanical engineers use their problem-solving superpowers to identify issues, come up with smart solutions, and make things run smoothly again.

Mechanical engineers encounter complex problems regularly. Effective problem-solving involves breaking down problems into manageable parts, identifying potential solutions, evaluating their feasibility, and implementing the best course of action.

By applying analytical thinking and systematic approaches, engineers can unravel complex scenarios, formulate hypotheses, and test solutions.

4. Mechanical Systems and Materials Knowledge

A deep understanding of mechanical systems, components, and materials is necessary. This includes knowledge of different types of mechanical systems (static, dynamic, etc.), their behaviors, and how different materials perform under various conditions.

Materials knowledge is a fundamental aspect of a mechanical engineer’s skill set, encompassing an understanding of different materials’ properties, behaviors, and applications.

Understanding the properties and behaviors of different materials helps engineers select the right material for each component based on factors like strength, durability, and environmental considerations.

These are some of the skills that are essential in the field of mechanical engineering. Other than this, soft skills that are required in the field of mechanical engineering are:

- Communication Skills:

- Clear communication skills are crucial for explaining technical concepts to both technical and non-technical audiences. Engineers must be able to convey design ideas, analysis results, and project updates effectively.

- Clear communication skills are crucial for explaining technical concepts to both technical and non-technical audiences. Engineers must be able to convey design ideas, analysis results, and project updates effectively.

- Teamwork and Collaboration:

- Mechanical engineers often work as part of interdisciplinary teams. Effective collaboration involves actively listening to team members, contributing ideas, resolving conflicts, and working together to achieve project goals.

- Mechanical engineers often work as part of interdisciplinary teams. Effective collaboration involves actively listening to team members, contributing ideas, resolving conflicts, and working together to achieve project goals.

- Project Management:

- Basic project management skills help engineers plan and execute projects efficiently. This involves setting goals, creating schedules, allocating resources, tracking progress, and managing budgets.

- Basic project management skills help engineers plan and execute projects efficiently. This involves setting goals, creating schedules, allocating resources, tracking progress, and managing budgets.

- Analytical Thinking:

- Analytical skills involve the ability to break down complex problems, analyze data, and draw conclusions based on evidence. Mechanical engineers use these skills to interpret simulation results, test data, and system behavior.

- Analytical skills involve the ability to break down complex problems, analyze data, and draw conclusions based on evidence. Mechanical engineers use these skills to interpret simulation results, test data, and system behavior.

- Attention to Detail:

- Paying attention to details is crucial in engineering. Small errors can lead to significant design flaws or safety issues. Engineers must be meticulous in design, analysis, and documentation.

- Paying attention to details is crucial in engineering. Small errors can lead to significant design flaws or safety issues. Engineers must be meticulous in design, analysis, and documentation.

Roles and Responsibilities of a Mechanical Engineer

Coming to the main part of the article, sorry to keep you waiting, but it is essential to understand what mechanical engineering and skills are required for it first. Since we covered that, let us jump to the role and responsibilities of a mechanical engineer:

1. Design and Development

Whatever you do in life, be it small, like deciding to buy a car, to something big like building a house, you need a plan for it. Without a proper plan, nothing will go properly. One of the important roles and responsibilities of a mechanical engineer is to design and develop plans that are required for the building of new technology.

The steps that go behind designing and developing a plan are:

a) Detailed Design Plans:

Mechanical engineers are responsible for creating detailed plans and specifications for mechanical systems, components, or products. This involves translating conceptual ideas into practical designs that can be manufactured and operated.

b) CAD Modeling:

They use computer-aided design (CAD) software to create 2D and 3D models of their designs. This allows them to visualize and manipulate the components, ensuring they fit together and function properly.

c) Simulation and Analysis:

Mechanical engineers perform simulations and analyses to evaluate factors like stress, strain, thermal behavior, and fluid dynamics. This helps ensure that the designs will meet performance requirements and function safely under various conditions.

d) Collaboration:

Mechanical engineers collaborate with other specialists, such as electrical engineers and industrial designers, to integrate mechanical components into larger systems. They work together to ensure all parts work harmoniously and meet the overall project goals.

2. Analysis and Testing

The important step in the process of manufacturing a product is analysis and testing. Building a product doesn’t end with production alone. Since this involves a lot of factors, it is important to analyse its performance of before releasing it into the market.

Testing is the stage where you have to test the manufactured product in real-time with users to gain insight about it. This also helps in deciding the areas that need improvement.

This is done in three stages:

a) Performance Evaluation:

Mechanical engineers use analytical tools and software to assess the performance of mechanical systems. This involves predicting how a design will behave under specific conditions, such as loads or temperature changes.

b) Testing and Prototyping:

They create prototypes and conduct physical testing to validate their designs. This may involve setting up experiments, collecting data, and making comparisons to expected outcomes.

c) Data Interpretation:

Mechanical engineers analyze and interpret the data gathered from tests and simulations. They identify any discrepancies between expected and actual performance and use this information to improve the design.

3. Project Management

The roles and responsibilities of a mechanical engineer do not stop with manufacturing and production alone, they also take part in managing projects.

For projects that involve industry-grade equipment, it is best to employ a person who knows about it and who has studied it as a project manager, and that’s why for such roles, mechanical engineers are preferred.

They will be helping out in the following ways:

a) Project Scoping:

Mechanical engineers define the scope, objectives, and deliverables of engineering projects. They establish clear project goals and a plan to achieve them.

b) Resource Management:

They allocate resources such as budget, time, and personnel effectively to ensure that projects stay on track and within constraints.

c) Coordination:

Mechanical engineers coordinate with team members, stakeholders, and other engineering disciplines to ensure everyone is aligned and working toward the same goals.

4. Manufacturing and Production

This is the core job of any mechanical engineer. The roles and responsibilities of a mechanical engineer are usually considered to be in the line of manufacturing and production, but as we saw earlier, it doesn’t stop there.

It is also important to note that every mechanical engineer should know the process of manufacturing and production, even if they are not a part of it.

Let us understand what all mechanical engineers do in this role:

a) Process Development:

Mechanical engineers develop manufacturing processes and methods that ensure efficient, cost-effective production of mechanical components or products.

b) Collaboration with Manufacturing Teams:

They work closely with manufacturing teams to implement the designed components and systems into the production line. This collaboration ensures that the manufacturing process is optimized and runs smoothly.

c) Problem Solving:

When issues arise during manufacturing, mechanical engineers troubleshoot and solve problems to ensure production quality and efficiency.

5. Quality Assurance and Control

One of the prominent roles and responsibilities of a mechanical engineer is to assure and control the quality of the product. No matter how good a mechanical engineer is, they are prone to make mistakes.

But in this field, mistakes can take the lives of people so it is mandatory to ensure the quality of the product as well as its working conditions before releasing it or using it.

These are the major steps involved in quality assurance and control:

a) Quality Standards:

Mechanical engineers establish and enforce quality control procedures and standards to ensure that products meet specifications and industry requirements.

b) Inspections and Audits:

They perform inspections and audits to verify that products adhere to established quality standards. This involves conducting thorough checks and assessments to identify any deviations or defects.

c) Continuous Improvement:

Mechanical engineers analyze data from quality control processes and identify areas for improvement. They then implement corrective actions to enhance product quality.

6. Maintenance and Repair

The major part of the work of a mechanical engineer happens after the release of a product. To ensure that the product works longer than intended, frequent maintenance and repairs must be done.

This helps in understanding the product’s nature and how long it can sustain in a real-world environment. This is one of the crucial roles and responsibilities of a mechanical engineer, as it is a cost-effective method.

Let us understand the processes that happen during maintenance and repair:

a) System Maintenance:

Mechanical engineers provide ongoing maintenance and support for mechanical systems, equipment, or machinery. This includes routine maintenance tasks, troubleshooting, and repairs.

b) Diagnosis:

They diagnose mechanical issues and malfunctions, identify the root causes and implement effective solutions.

c) Preventive Maintenance:

Mechanical engineers develop schedules and procedures for preventive maintenance to minimize downtime and ensure the reliable operation of systems.

7. Research and Innovation

Mechanical engineers also indulge in research and innovation. The R&D department that you see in most companies comprises people like these. This is considered to be one of the most important roles and responsibilities of a mechanical engineer because this paves the way for future tech.

We cannot develop unless we change. This is a core principle for research and innovation, where mechanical engineers try to change things that are happening right now to develop something that is new and profound.

These are the processes behind research and innovation:

a) Technology Research

Mechanical engineers stay informed about new technologies, materials, and methods that could improve product performance, efficiency, and innovation.

b) Concept Development

They contribute to the development of innovative solutions to engineering challenges, pushing the boundaries of what’s currently possible.

c) R&D Projects

Mechanical engineers participate in research and development projects that contribute to the advancement of the field, experimenting with new concepts and ideas.

These roles and responsibilities highlight the breadth of tasks that mechanical engineers undertake throughout the lifecycle of projects, from initial design and development to manufacturing, testing, and ongoing maintenance. The specific tasks you’ll encounter will depend on the industry, company, and your role within the engineering team.

You can consider enrolling yourself in GUVI’s CAD Course for Mechanical Engineers, which lets you gain practical experience by developing real-world projects and covers technologies including AutoCAD, Solidworks, CATIA, Ansys, GD&T, etc.

Conclusion

In conclusion, the vast roles and responsibilities of a mechanical engineer explain their importance across diverse industries. From designing innovative products and systems to analyzing complex mechanical behaviors, mechanical engineers are the driving force behind technological advancements that shape our modern world.

With an ever-evolving technical landscape, mechanical engineers remain at the forefront of innovation, using their skills to take mankind into a new era of engineering excellence.

FAQ

Mechanical engineers are involved in designing engines, machines, consumer products, manufacturing systems, HVAC systems, and more.

While not always mandatory, basic programming skills can be beneficial for automating tasks, data analysis, and simulations.

Mechanical engineers face challenges related to sustainability, energy efficiency, rapid technological changes, and integrating complex systems.

Mechanical engineers innovate by developing new technologies, optimizing existing systems, and creating solutions to complex engineering problems.

The future of mechanical engineering holds exciting opportunities for developing sustainable technologies, advancing automation, and contributing to global progress.

![A Complete Look on Mechanical Engineer's Salary in India [2025] 14 Feature image - A Complete Look on Mechanical Engineer’s Salary in India](https://www.guvi.in/blog/wp-content/uploads/2023/09/Feature-image-A-Complete-Look-on-Mechanical-Engineers-Salary-in-India.webp)

Fantastic post! You’ve highlighted key responsibilities that truly define the role of a mechanical engineer. From designing systems to ensuring safety and efficiency, each task plays a critical part in innovation. It’s great to see a clear breakdown of these roles, especially for aspiring engineers. Keep up the great work

this is amazing and educative, it displays an art of teaching yet retains the conscience of a person who has experience in the field.