12 Magical Mechanical Engineering Tools in 2024

Sep 04, 2024 13 Min Read 11146 Views

(Last Updated)

If you watch any movie, there will always be a sidekick who supports the hero till the end. In a similar way, tools play the role of a sidekick to heroes that is engineers. Especially in the field of mechanical engineering, it is mandatory that everyone should know about mechanical engineering tools.

Don’t worry if you don’t know about it as we are here to help you with that. In this article, we listed down the top 12 mechanical engineering tools that are important in the field of mechanical engineering. Let us understand them one by one

Table of contents

- Importance of Mechanical Engineering Tools

- Top Mechanical Engineering Tools

- Computer-aided design (CAD)

- Computer-Aided Engineering (CAE) Software

- 3D Printers

- Hand Tools

- Power Tools

- CNC Machines

- Material Testing Equipment

- Simulation and modeling software

- FMEA Software

- Fluid Mechanics Equipment

- Thermal Analysis Software

- Safety Equipment

- Conclusion

- FAQ

- What is mechanical engineering, and what do mechanical engineers do?

- What technical skills are essential for a career in mechanical engineering?

- What soft skills are beneficial for mechanical engineers?

- What are some common hand tools used in mechanical engineering?

- What is the significance of Computer-Aided Design (CAD) software in mechanical engineering?

Importance of Mechanical Engineering Tools

Before studying mechanical engineering tools, let us first understand the importance of it. Mechanical engineering tools are like the hands and brains of mechanical engineers. They’re incredibly important because they help engineers design, build, and fix things more efficiently and accurately.

Imagine trying to build a house without a hammer or a screwdriver—it would be very challenging and time-consuming.

Similarly, tools in mechanical engineering are essential for:

- Design: Engineers use tools like computer software and 3D modeling to create detailed plans and drawings of machines and structures.

- Construction: Tools like drills, saws, and welding machines are used to build and assemble mechanical systems and products.

- Maintenance: Engineers use tools to repair and maintain machinery and equipment to keep them working correctly and safely.

- Testing and Analysis: Specialized tools help engineers test materials, measure performance, and ensure the quality and safety of their designs.

To put it simply, tools are the backbone of mechanical engineering, making it possible to turn ideas into reality, keep things running smoothly, and ensure safety and reliability in the world of machines and technology.

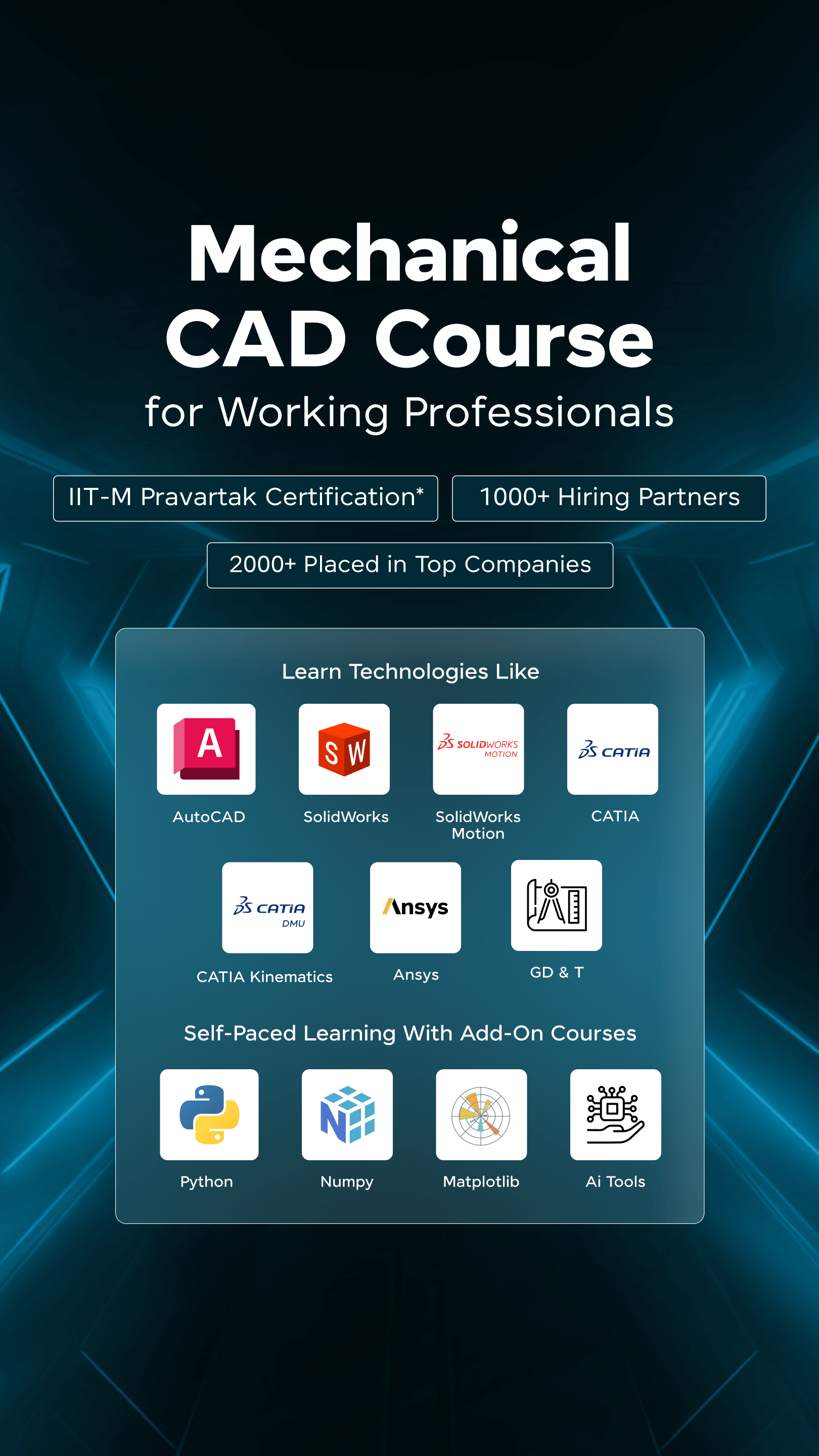

Before we move on to the next part, you should have a deeper knowledge of key mechanical engineering concepts. You can consider enrolling yourself in GUVI’s CAD Program for Mechanical Engineers, which lets you gain practical experience by developing real-world projects and covers technologies including AutoCAD, Solidworks, CATIA, Ansys, GD & T, etc.

Additionally, if you would like to explore AutoCAD for Mechanical Engineering through a self-paced course, you can take GUVI’s AutoCAD Mechanical Certification Course.

Top Mechanical Engineering Tools

In the previous section, you saw the importance of mechanical engineering tools. Make sure to learn and understand the skills required for a mechanical engineer as tools are just a catalyst to your skills, if there are no skills, then the tools are of no use.

Mechanical engineering is a diverse field, and engineers often use a wide range of tools and equipment to design, analyze, and build mechanical systems and products.

Here are some of the top mechanical engineering tools and equipment commonly used in the industry:

1. Computer-aided design (CAD)

Computer-aided design (CAD) software is a computer program that every mechanical engineer should know as that helps engineers, architects, and designers create detailed drawings and 3D models of objects and structures. It’s like a digital drawing tool, but much more powerful. This is one of the most powerful mechanical engineering tools in a mechanical engineer’s arsenal

Here’s how CAD software works:

- Drawing and Designing:

CAD software allows you to draw shapes, lines, and curves on a computer screen, just like you would with a pencil on paper. However, it’s much more precise and flexible. You can easily make changes, move things around, and create complex designs. - 3D Modeling:

CAD also lets you build three-dimensional (3D) models of objects. This is incredibly useful for designing buildings, machinery, or products because you can see how all the parts fit together in a virtual 3D space. - Measurement and Precision:

CAD software is incredibly precise. You can specify exact measurements for every part of your design, down to tiny fractions of an inch or millimeter. This accuracy is crucial for making sure things fit together perfectly when they’re built in the real world. - Visualization:

CAD software often includes features that help you visualize your design differently. You can view it from different angles, add textures and colors, and even simulate how it will work or move. - Collaboration:

CAD files can be easily shared with others, which is essential for teamwork. Engineers, architects, and manufacturers can all work on the same design, even if they’re in different locations. - Automation:

Some CAD software can automate repetitive tasks. For example, if you’re designing a gear, you don’t have to draw every tooth individually; the software can do it for you based on your specifications. - Analysis:

Many CAD programs can analyze your design for things like strength, stress, and how fluids or air will flow through it. This helps engineers ensure that their designs are safe and functional.

In a nutshell, CAD software is like a digital toolkit for designers and engineers. It allows them to create, modify, and analyze complex designs with incredible precision and efficiency, making the process of designing everything from skyscrapers to tiny electronic components much more manageable and accurate.

2. Computer-Aided Engineering (CAE) Software

Computer-aided engineering (CAE) software is a powerful computer program and is one of the important mechanical engineering tools that helps engineers and scientists understand how things will behave in the real world without having to build physical prototypes. It’s like a virtual testing and simulation tool for all sorts of designs and systems.

Here’s how CAE software works:

- Virtual Testing:

Imagine you’re designing a new car. Instead of building a real car and crashing it to see how it performs in a collision, CAE software lets you create a digital model of the car. You can then simulate crashes on the computer to see what happens, whether the car’s structure will hold up, and if passengers will be safe. This helps engineers make cars safer without wasting resources on physical tests. - Simulation:

CAE software simulates how things will behave under different conditions. For instance, it can predict how an airplane wing will perform in various weather conditions or how a bridge will handle heavy traffic. This is incredibly useful for designing and testing complex systems. - Stress Analysis:

Engineers can use CAE to see how much stress and strain different parts of a structure or machine will experience. This helps them make sure that these parts won’t break or wear out too quickly. - Fluid Dynamics:

CAE is often used to simulate how liquids or gases (fluids) will flow through pipes, turbines, or even blood vessels. For example, it can help design efficient cooling systems for electronics or study how blood flows in arteries. - Heat Transfer:

CAE can model how heat moves through materials and systems. This is vital for designing things like ovens, engines, and even electronic devices to prevent overheating. - Optimization:

CAE software can help find the best design by testing multiple variations quickly. Engineers can change parameters like shape, size, or materials and see how they affect performance, cost, or efficiency. - Safety and Reliability:

Engineers use CAE to identify potential problems and weaknesses in designs before they become real issues. It helps ensure that products and structures are safe and reliable. - Time and Cost Savings:

CAE saves a lot of time and money because it eliminates the need to build and test physical prototypes, which can be expensive and time-consuming.

CAE software is like a digital laboratory that lets engineers and scientists explore how things work and behave in the virtual world. It helps them make informed decisions, improve designs, and avoid costly mistakes before anything is built in the real world.

3. 3D Printers

3D printers are magical machines that can turn digital designs into real, physical objects. Think of them as a bit like the replicators you might see in science fiction shows. Amidst all the mechanical engineering tools, this one has the most interesting feature.

3D printers work in the following ways:

- Digital Design:

Everything starts with a digital design of the object you want to create. This design is made using special software like Computer-Aided Design (CAD). It’s like drawing the thing you want to make on a computer. - Slicing:

The 3D printer takes this digital design and slices it into very thin layers, like a loaf of bread. Each of these slices is a set of instructions that tells the printer how to build that particular layer. - Printing:

The printer then starts at the bottom and slowly builds the object one layer at a time. It does this by melting or depositing material (usually plastic, metal, or resin) in precise locations according to the instructions from the digital design. - Layer by Layer:

The layers start to stack on top of each other, and as they do, they fuse together to form the final 3D object. It’s a bit like making a sculpture out of many thin sheets of material. - Cooling and Solidifying:

If it’s a plastic 3D printer, the melted plastic cools down quickly and hardens to form a solid object. If it’s a resin printer, a special light is used to harden the resin. Metal printers use lasers or electron beams to melt and fuse metal powder. - Removal and Cleanup: Once the printing is done, you might need to remove the object from the printer and do some finishing touches like sanding or painting to make it look just right.

What’s cool about 3D printers is that they can create almost anything you can imagine, from simple toys to complex machine parts, custom jewelry, and even prosthetic limbs. They’re used in various fields, including manufacturing, medicine, aerospace, and even in people’s homes for creative projects.

4. Hand Tools

Hand tools are like your trusty helpers for doing all sorts of tasks that require cutting, gripping, twisting, or hitting things. These tools don’t need electricity or any fancy mechanisms; you use your hands and muscle power to operate them. In the list of mechanical engineering tools, this one is a practical one and needs practical experience for it.

Here are some common hand tools and what they do, explained in simple terms:

- Screwdriver:

It’s a tool with a handle and a metal shaft with a special tip. You use it to turn screws to fasten or unfasten them. Imagine using a screwdriver to assemble furniture or open a battery compartment. - Wrench:

This tool looks like a metal or plastic handle with a jaw-like opening at one end. It’s used to tighten or loosen nuts and bolts. Think of fixing a bicycle with a wrench. - Pliers:

Pliers have two handles and a hinged, gripping part at the tip. They are great for gripping, bending, and cutting wires or small objects. They’re like your tool for holding onto things securely. - Hammer:

Hammers have a heavy metal head (the part you swing) and a handle. They’re used for driving nails into wood or pounding things together. Imagine hanging a picture with a nail and a hammer. - Saw:

A saw is a tool with a sharp-toothed edge. You move it back and forth to cut through things like wood or metal. It’s like a manual version of an electric saw. - Tape Measure:

This is a flexible ruler in a case. It’s used to measure lengths accurately, like when you’re figuring out if a piece of furniture will fit in your room. - Utility Knife:

It’s a small, retractable knife with a sharp blade. You use it for cutting things like cardboard, tape, or opening packages. - Screwdriver Set:

A set of screwdrivers with different tips to fit different types of screws. It’s like having multiple tools in one kit. - Clamps:

These tools are used to hold things tightly together, like two pieces of wood while glue dries. They come in various shapes and sizes. - Chisel: A chisel has a sharp, flat blade and a handle. It’s used for carving or cutting wood or metal. Think of it like a sculptor’s tool.

These hand tools are versatile and essential for various DIY projects, repairs, and construction work. They don’t need electricity or batteries, and they rely on your physical effort to get the job done.

Whether you’re fixing something around the house or working on a creative project, hand tools are your dependable companions for getting things done with your own two hands.

5. Power Tools

Power tools are like the superheroes of mechanical engineering tools. They’re designed to make tasks faster, easier, and more efficient by using electricity or compressed air to do the hard work.

These tools are typically used in construction, woodworking, metalworking, and other industries where strength and speed matter. Let’s explore some common power tools and what they do:

- Drill:

A power drill is like a supercharged screwdriver. It spins a bit rapidly, making it easy to make holes in various materials like wood, metal, or concrete. You can also attach screwdriver bits to it for driving screws. - Circular Saw:

Think of a circular saw as an electric knife for cutting wood and other materials. It has a round, spinning blade that can cut through straight or curved lines quickly. - Jigsaw:

A jigsaw is a power tool that can cut curved or irregular shapes in wood, metal, or plastic. It’s handy for making intricate cuts, like when you’re crafting or working on detailed woodworking projects. - Miter Saw:

This tool is perfect for making precise angled cuts in wood. It’s commonly used in carpentry for cutting pieces at specific angles, such as for making picture frames or molding. - Table Saw:

A table saw is a large, powerful tool with a circular blade that protrudes from a tabletop. It’s excellent for making straight and precise cuts in various materials, especially large sheets of wood. - Reciprocating Saw:

This tool is like a high-powered handsaw on steroids. It’s used for cutting through tough materials like metal pipes, nails, and even tree branches with a back-and-forth motion. - Angle Grinder:

Angle grinders are versatile tools with a spinning abrasive wheel. They’re used for cutting, grinding, and polishing metal, stone, or concrete. - Nail Gun:

A nail gun is a rapid-fire tool that shoots nails into wood or other materials. It’s much faster than manually hammering nails and is commonly used in construction and carpentry. - Power Planer:

This tool helps you shave thin layers of wood, making surfaces smooth and even. It’s handy for leveling and smoothing out rough lumber. - Belt Sander: A belt sander is used to sand large areas of wood quickly. It has a continuous sanding belt that moves in a loop, making it efficient for smoothing rough surfaces.

These power tools are essential for professional tradespeople and DIY enthusiasts alike. They save time and effort and make it possible to tackle a wide range of projects efficiently. However, they should be used with care and safety precautions to prevent accidents and injuries.

6. CNC Machines

CNC (Computer Numerical Control) machines are like incredibly smart and precise robots that help make all sorts of things, from intricate metal parts to detailed wooden carvings. They’re like magic machines in mechanical engineering tools that follow precise instructions to create complex objects with amazing accuracy.

Here’s how CNC machines work in simple terms:

- Design:

First, someone creates a digital design of the object they want to make. This design is made using special software, like a digital blueprint or plan. - Instructions:

Next, these digital designs are turned into a set of very detailed and precise instructions. It’s like telling the CNC machine exactly what to do step by step. - Loading Material:

You put the material you want to work on (like metal, wood, or plastic) onto the CNC machine’s work table. It’s kind of like putting a piece of paper into a printer. - Precision Control:

The CNC machine has motors and tools that move in three dimensions (up and down, side to side, and back and forth). It uses these movements to precisely cut, shape, drill, or carve the material based on the instructions it received. - Constant Monitoring:

The machine is really smart—it constantly checks its progress and adjusts to make sure everything is perfect. It knows exactly where to cut and how deep to go. - Finished Product: When the machine is done, it has turned a plain piece of material into a finished object that matches the digital design exactly.

CNC machines are used in many industries, including manufacturing, aerospace, automotive, and even in hobbyist workshops. They’re amazing because they can create complex and precise objects over and over again, and they work 24/7 without getting tired or making mistakes.

Imagine you wanted to make a hundred identical chess pieces or create a custom metal bracket for a machine. CNC machines can do that with incredible speed and accuracy, making them essential tools for modern manufacturing and craftsmanship.

7. Material Testing Equipment

Material testing equipment is one of the essential mechanical engineering tools and it is a set of tools that help scientists and engineers figure out how strong, durable, and safe different materials are. These materials could be anything from metals and plastics to rubber or even concrete. It’s like checking if a piece of cake is soft and tasty or hard and stale, but for stuff we build with.

Here’s how material testing equipment works:

- Sample Preparation:

First, you take a small piece or sample of the material you want to test. It’s like taking a tiny slice of that cake. - Pulling and Pushing:

Some tests involve pulling the material apart (tension testing) or pushing it from the sides (compression testing). This helps figure out how much force it can handle before breaking or deforming. - Bending and Twisting:

In other tests, you might bend the material or twist it. This helps you understand how flexible or stiff it is. - Squishing and Squeezing:

For materials like foam or rubber, there are tests where you squish or squeeze the material to see how it reacts under pressure. - Heat and Cold:

Some materials might be tested under extreme temperatures to see how they behave when it’s really hot or freezing cold. - Measuring Instruments:

Special machines and instruments are used to apply the force or temperature and measure how the material responds. These instruments are super accurate and can detect even tiny changes. - Recording Data:

As all this happens, the equipment records lots of data, like how much force was applied, how the material moved, and how it reacted. - Analysis:

Scientists and engineers look at all this data to understand the material’s properties. They can figure out things like how much weight a bridge made from this material can hold or whether a plastic used in a toy is safe for kids to play with.

Material testing equipment is essential because it helps ensure that the materials we use in buildings, vehicles, machines, and everyday products are safe and reliable. It’s like giving materials a test to make sure they meet certain quality standards before we trust them in real-world applications.

8. Simulation and modeling software

Simulation and modeling software is like a digital laboratory for mechanical engineers and it helps them understand and predict how things will work without having to build them in the real world. It’s like a super-smart computer game where you create virtual versions of things to test and experiment with.

Here’s how simulation and modeling software of mechanical engineering tools work in simple terms:

- Create a Digital Copy:

First, you make a computerized copy of whatever you’re interested in. This could be a car, a weather system, an airplane wing, or even a chemical reaction in a lab. It’s like making a virtual clone. - Set Up the Rules:

You tell the computer how the virtual world should work. For example, if you’re simulating a car crash, you specify the speed, the weight of the car, and the materials it’s made of. It’s like creating the rules for your computer game. - Run the Simulation:

Then, you press a button, and the software starts running the simulation. It uses math and physics to calculate what should happen based on the rules you set up. - Observe and Learn:

You watch the simulation as it plays out on your computer screen. You can see how the car crumples in the crash, how a storm develops, or how a bridge behaves under heavy loads. - Make Changes:

If you want to see what happens if you change something, like making the car heavier or the storm stronger, you can do that in the virtual world without any real-world consequences. It’s like experimenting without risk. - Gather Data:

The software records lots of data during the simulation—things like temperatures, pressures, movements, or stresses. This data helps you understand how everything is behaving. - Analysis: After the simulation is done, you analyze the data to draw conclusions. For example, you might learn that a certain design for a bridge is strong enough to support heavy trucks.

Simulation and modeling software are used in various fields. Scientists use them to understand natural phenomena, engineers use them to design and test products, and even video game designers use them to create realistic game worlds.

9. FMEA Software

FMEA (Failure Modes and Effects Analysis) software is like a digital tool that helps engineers and teams identify and prevent problems before they happen in a product, process, or system. It’s like having a crystal ball that shows you where things might go wrong and helps you stop those issues from causing trouble in the real world.

Here’s how FMEA software works in simple terms:

- List Possible Failures:

First, you make a list of all the things that could go wrong with your product or process. These are called “failure modes.” For example, if you’re designing a car, a failure mode might be the brakes not working. - Rate Severity:

You then decide how bad each failure would be if it happened, using a scale. For instance, a brake failure in a car would be rated very high because it’s dangerous. - Rate Likelihood:

You estimate how likely each failure is to occur. For example, the chance of brake failure might be low if you have a good design and quality control. - Rate Detectability:

You assess how easily you can catch the failure before it causes harm. If a brake failure can be easily detected during routine inspections, it gets a higher rating for detectability. - Calculate Risk Priority:

FMEA software uses these ratings to calculate a “risk priority” for each failure mode. This helps you focus on the most critical issues—those with the highest risk priority. - Take Action:

Once you know which failures are most critical, you can brainstorm and implement ways to prevent or mitigate them. This might involve design changes, better quality control, or adding safety features. - Track Progress:

FMEA software helps you keep track of what actions you’ve taken and their effectiveness in reducing risks. - Continuous Improvement: Teams often use FMEA software throughout a project’s life cycle to continuously monitor and improve risk management.

FMEA software is used in various industries, such as automotive, aerospace, healthcare, and manufacturing. It’s a proactive approach to ensure that products and processes are as reliable and safe as possible by addressing potential issues early in the design or production process.

In simple terms, FMEA software is like a safety and reliability advisor for engineers and teams, helping them spot and fix problems before they become big and costly headaches. It’s all about making sure things work smoothly and safely in the real world.

10. Fluid Mechanics Equipment

Fluid mechanics equipment is a set of tools and devices that scientists and engineers use to study and understand how liquids and gases (fluids) behave and flow. It’s like having a special kit to investigate how water moves in rivers, how air flows over an airplane wing, or how oil moves through pipes in a factory.

Here’s how fluid mechanics equipment works in simple terms:

- Flow Measurement:

These tools help measure how fast and how much fluid is moving through a pipe or a channel. It’s like using a speedometer for liquids and gases. - Pressure Measurement:

These devices tell you how much pressure a fluid is exerting. For example, they help engineers figure out how much pressure is inside a water pipe or an aircraft’s fuel tank. - Pumps and Fans:

These machines are like the heartbeats of fluid systems. Pumps push liquids, while fans or blowers move air. They’re used in everything from water treatment plants to cooling systems in computers. - Valves:

Valves are like gates that control the flow of fluids. They can open or close, or they can adjust the flow rate. You’ll find them in faucets, pipelines, and various industrial systems. - Tanks and Reservoirs:

These containers store fluids and help researchers understand how they behave when stored or moved. It’s like studying how water behaves in a big bathtub. - Turbines:

Turbines are like windmills, but they work with fluids instead of air. They convert the energy from flowing fluids into useful power, like in hydroelectric dams or aircraft engines. - Nozzles and Diffusers:

These are like special shapes that change the speed and direction of fluids. Nozzles speed up fluids (like in a garden hose), while diffusers slow them down. - Flow Visualization:

Special equipment, like dye injection or laser-based techniques, helps scientists see how fluids move and behave. It’s like adding colorful paint to water to see how it flows in a river. - Lab Apparatus: In laboratories, you’ll find smaller-scale equipment like flumes, wind tunnels, and flow channels. These recreate fluid behavior for experiments and testing.

Fluid mechanics equipment is crucial in various fields, including civil engineering (for designing water supply systems), aerospace (for designing aircraft and rockets), and even weather prediction (to understand atmospheric fluid dynamics).

11. Thermal Analysis Software

Thermal analysis software is like a digital tool that helps scientists and engineers understand how heat moves through objects and systems. It’s like having a virtual heat detective that can predict how hot or cold things will get, which is crucial for designing things like buildings, electronics, and even cooking appliances.

Here’s how thermal analysis software works in simple terms:

- Create a Digital Model:

First, you create a computerized model of the object or system you’re interested in. This model includes details like the material it’s made of, its shape, and how heat might be applied to or removed from it. - Set Up Conditions:

Next, you tell the software how hot or cold it is outside (the environmental conditions) and how heat is generated or transferred within the object or system. For example, you might simulate how a computer chip heats up during use. - Run the Simulation:

You press a button, and the software starts running a simulation. It uses math and physics to calculate how heat flows through the model over time. - Visualize Results:

As the simulation runs, you can see how temperatures change within the object or system. It might show you which parts get hot and which stay cool. - Analyze Data:

The software records lots of data, like temperature distributions, heat flow rates, and more. You use this data to understand how well the object or system is performing in terms of managing heat. - Make Improvements:

If you discover that some parts are getting too hot or too cold, you can use the software to test design changes or materials to improve the thermal performance. - Optimize: Through repeated simulations and adjustments, you can optimize the object or system to work as efficiently and safely as possible, managing heat effectively.

Thermal analysis software is used in various industries, including architecture (for designing energy-efficient buildings), electronics (for keeping devices cool), and manufacturing (for processes involving heating and cooling).

It helps ensure that products and systems don’t overheat or freeze and that they work as intended under different temperature conditions.

12. Safety Equipment

Safety equipment refers to special gear and devices that people wear or use to protect themselves from various dangers and hazards while doing certain activities or working in specific environments. These tools are like personal shields that help keep you safe from harm.

Here are some common types of safety equipment and what they do, explained in simple terms:

- Hard Hats:

Hard hats are like protective helmets that people wear on construction sites or in industrial settings. They shield your head from falling objects, debris, or low-hanging hazards. - Safety Glasses:

These are like strong, clear glasses that protect your eyes from flying particles, chemicals, or bright light. They’re essential for tasks like woodworking or using power tools. - Ear Protection (Earplugs or Earmuffs):

Ear protection is like noise-canceling headphones for your ears. They reduce loud noises and prevent hearing damage, which is crucial in noisy workplaces like factories or construction sites. - Respirators:

Respirators are like special masks that filter out harmful dust, fumes, gases, or airborne particles. They’re used in situations where the air might be polluted or contain dangerous substances. - Safety Gloves:

Safety gloves are like protective armor for your hands. They shield your skin from cuts, burns, chemicals, or rough surfaces. Different gloves are designed for various types of work. - Safety Boots:

These are like extra-sturdy shoes with reinforced toes. They protect your feet from heavy objects, sharp materials, or electrical hazards, commonly used in construction or manufacturing. - High-Visibility Clothing:

These are like super-bright clothes designed to make you easily visible, even in low light or bad weather. They’re worn by construction workers, cyclists, and road workers to prevent accidents. - Fall Protection Equipment (Harnesses, Safety Belts, Lanyards):

This equipment is like a safety net for people working at heights, like on roofs or scaffolding. It prevents falls and keeps workers secure. - Fire Extinguishers:

Fire extinguishers are like handy firefighting devices. They help put out small fires before they become big and dangerous. Everyone should know how to use them. - Safety Signs and Labels:

These are like visual warnings that alert you to potential dangers. You’ve probably seen signs like “Caution: Wet Floor” or “No Smoking” in public places. - First Aid Kits:

First aid kits are like medical toolboxes that contain essential supplies for treating minor injuries. They can be a lifesaver in emergencies. - Safety Goggles: Similar to safety glasses, safety goggles provide extra protection by forming a seal around your eyes, guarding against splashes, and chemical exposure.

Safety equipment is critical because it helps prevent accidents, injuries, and even fatalities in various settings like workplaces, construction sites, laboratories, and recreational activities.

It’s like having a shield that keeps you safe while you do your job or enjoy your hobbies. Always use the appropriate safety equipment when needed to protect yourself and others.

Kickstart your career by enrolling in GUVI’s CAD Career Program for Mechanical Engineers where you will master technologies including AutoCAD, Solidworks, CATIA, Ansys, GD & T, etc, and build interesting real-life mechanical projects.

Alternatively, if you would like to explore AutoCAD for Mechanical Engineering through a self-paced course, you can take GUVI’s AutoCAD Mechanical Certification Course.

Conclusion

In conclusion, mechanical engineering relies on a wide array of essential tools to bring innovative ideas to life, maintain existing systems, and ensure safety and precision.

From the power of computer-aided design (CAD) software to the strength of wrenches and drills, these tools are the backbone of mechanical engineering. They enable engineers to design, build, and maintain the machines and structures that shape our modern world.

These tools not only make the work more efficient but also pave the way for groundbreaking advancements in technology and industry. In the ever-evolving field of mechanical engineering, the right tools are not just instruments but partners in progress.

FAQ

What is mechanical engineering, and what do mechanical engineers do?

Mechanical engineering is a branch of engineering that focuses on designing, analyzing, and manufacturing mechanical systems and devices. Mechanical engineers work on a wide range of projects, from designing automobiles to developing robotics.

What technical skills are essential for a career in mechanical engineering?

Essential technical skills include proficiency in CAD software, knowledge of materials and manufacturing processes, and an understanding of thermodynamics and mechanics.

What soft skills are beneficial for mechanical engineers?

Soft skills such as communication, time management, adaptability, and attention to detail are valuable in a mechanical engineering career.

What are some common hand tools used in mechanical engineering?

Common hand tools include wrenches, screwdrivers, pliers, hammers, and tape measures.

What is the significance of Computer-Aided Design (CAD) software in mechanical engineering?

CAD software allows engineers to create and design 2D and 3D models of mechanical parts and systems, enabling precise and efficient product development.

Ggggreat